Optimizing Water Management in a Bangkok, Thailand Cement Factory with Foras MA-Series Pumps

- Alexander Avramenko

- Mar 26, 2025

- 2 min read

Updated: Apr 30, 2025

Location: Thailand - Bangkok

Year: 2018

Application: Cement Factory

Project Overview

A leading cement manufacturing plant faced operational inefficiencies due to inadequate water management in its production processes. The factory required a reliable, high-performance pumping system to handle water circulation for cooling, dust suppression, and other essential functions. To ensure uninterrupted production and enhanced efficiency, the company turned to FORAS.

The Challenge

Cement factories operate in harsh environments where equipment is exposed to abrasive materials, extreme temperatures, and continuous usage. The plant faced several issues:

✔ Frequent pump failures due to wear and tear

✔ High maintenance costs and production downtime

✔ Inconsistent water supply affecting cooling and dust suppression

✔ Energy inefficiency, increasing operational expenses

The plant needed a robust and energy-efficient pumping system capable of withstanding demanding industrial conditions while ensuring reliable water circulation.

Our Solution: FORAS MA Series Pumps

To address these challenges, we implemented FORAS MA Series pumps, known for their durability, efficiency, and high-performance capabilities in industrial applications.

Why FORAS MA Series Pumps?

Built for Heavy-Duty Applications – Designed with cast iron construction, ensuring durability and longevity in tough environments.

High Efficiency – Hydraulic optimization ensures maximum performance while reducing energy consumption

Reliable Performance – Designed for continuous operation, minimizing downtime and maintenance costs.

Versatile Applications – Ideal for cooling systems, water transfer, and dust suppression in cement production

Easy Maintenance – Simplified design for quick servicing and minimal disruptions.

With motor:

Or stand alone:

Implementation Process

Assessment – The plant’s water requirements were analysed and determined.

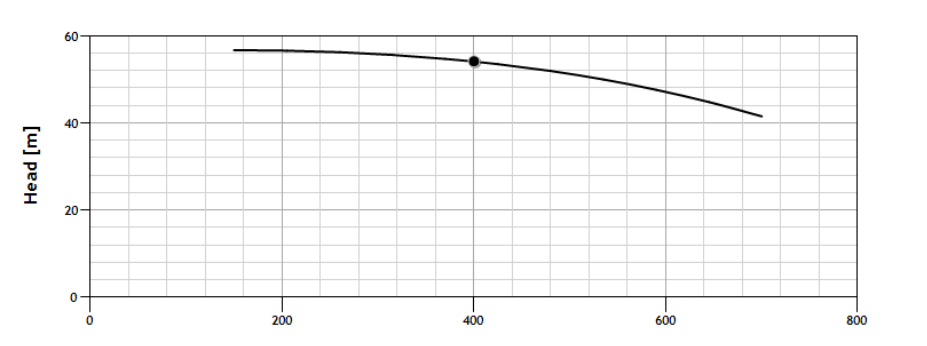

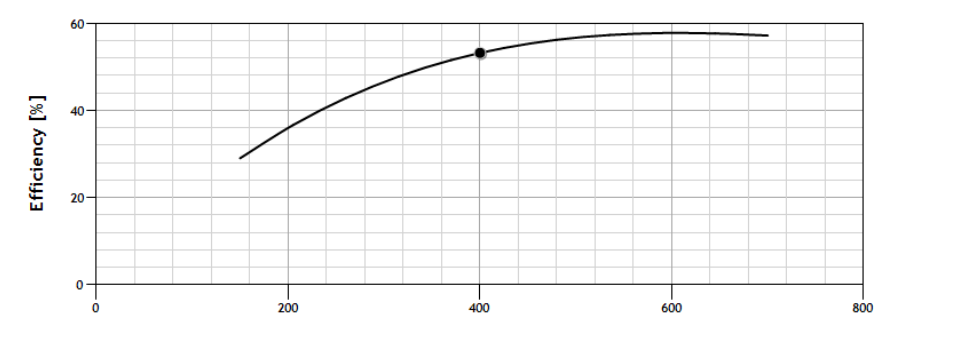

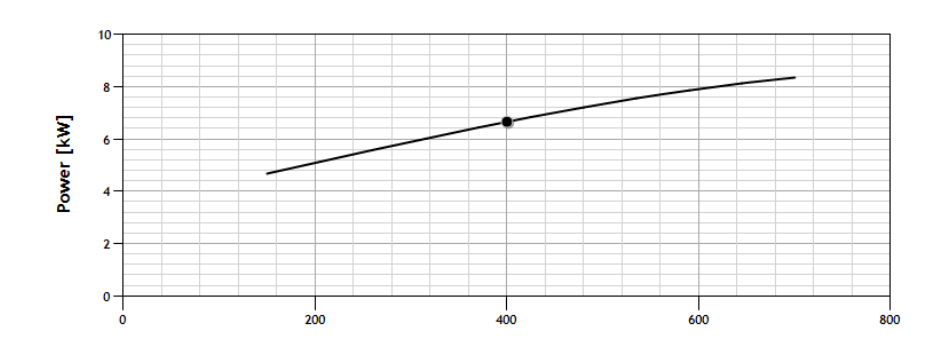

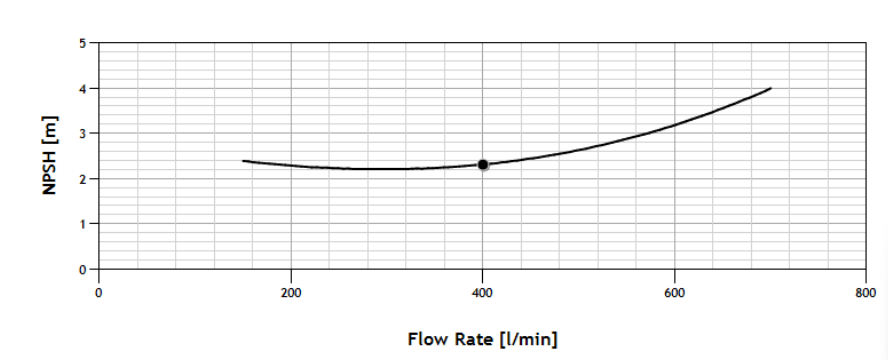

Custom Selection – FORAS MA Series pump was selected to ensure a perfect balance between flow rate Q: 400 l/min and pressure H: 54.1 m, optimising for efficiency η: 53.18% and power: 6.66 kW.

*MEI ≥ 0,4 (regulation EU N. 547/2012) Tolerances according to UNI ISO 9906 grade 3B

Alternative models were considered:

With stainless steel MAX40-200A, however, stainless steel was not needed.

and a more compact version of the pump with motor together: MN40-200A. However, the design of MA40-200A+MOT132S was deemed a better choice as it allows for easier motor repair and replacement.

Ready to go – The new system was installed seamlessly.

Results: Enhanced Efficiency & Cost Savings

✅ 30% Reduction in Energy Costs – Thanks to the pumps’ high-efficiency design

✅ 50% Increase in Pump Lifespan – Durable materials and optimized operation reduced wear and tear

✅ Minimized Downtime – Reliable performance ensured continuous production flow

✅ Improved Water Management – Consistent supply for cooling and dust suppression

By integrating FORAS MA Series pumps, the cement factory significantly improved its water management system, achieving cost savings, operational efficiency, and long-term sustainability. This case highlights the importance of selecting the right industrial pumps to optimize processes and maximize productivity.

Post-sales support

We offer all the spare parts for all Foras pumps and ship globally.

Alternatives and upgrades?

A more compact version:

For sea-water and heavier demands, we offer an upgrade to the stainless steel version MAX40-200A:

and standalone:

If you need a similar pump?

Tell us your pressure (m) and water capacity (l/min) requirements, and our team of specialists will be happy to pick the best pump for you and offer you a quote for shipping globally!